1. The hazards, causes and types of multi-point ground faults in the transformer core

1. The hazards of multi-point ground faults in the core

During normal operation of the transformer, the core cannot be grounded at multiple points. During normal operation of the transformer, there is an alternating magnetic field around the winding. Due to electromagnetic induction, there are parasitic capacitances between the high-voltage winding and the low-voltage winding, between the low-voltage winding and the core, and between the core and the shell. The live winding will be coupled through the parasitic capacitance. , causing the core to generate a floating potential against the ground. Since the distance between the core and other metal components and the winding is not equal, there is a potential difference between the components. When the potential difference between the two points reaches a level that can breakdown the insulation between them, Spark discharge is generated, which is intermittent and has adverse effects on transformer oil and solid insulation in the long run.

In order to eliminate this phenomenon, the core and the shell are reliably connected so that they are at the same potential as the shell. However, when the core or other metal components are grounded at two or more points, the grounding point will form a closed loop, causing circulation and causing Local overheating will cause oil decomposition and insulation performance degradation. In severe cases, the core silicon steel sheet will be burned out and cause a major accident of the main transformer. Therefore, the core of the main transformer can only be grounded at one point.

2. Causes of core ground fault

Transformer core grounding faults mainly include: short circuit of the grounding plate due to poor construction technology and design; multi-point grounding caused by accessories and external factors; burrs, rust, welding slag and other factors caused by metal foreign objects left in the main transformer and poor core technology Cause grounding.

3. Types of core failures

There are six common fault types in transformer cores:

(1) The iron core hits the shell and the clamp. During the installation, due to negligence, the stable nails for transportation on the top cover of the fuel tank were not turned over or removed, causing the iron core to collide with the tank shell; the iron core clamp limb plate touched the iron core column; the silicon steel sheet warped and touched the clamp limb plate; the iron core was clamped under The cardboard between the piece's feet and the iron yoke fell off, and the feet collided with the silicon steel sheet; the thermometer seat cover was too long and collided with the clamp, iron yoke, and core column, etc.

(2) The steel seat cover of the core bolt is too long and short-circuited with the silicon steel sheet.

(3) There is foreign matter in the fuel tank, causing the silicon steel sheet to partially short-circuit. For example, a 31500/110 power transformer in a substation in Shanxi experienced multi-point grounding in the core, and a screwdriver with a sky handle was found between the clamp and the iron yoke on the hanging cover; a 60000/220 power transformer in another substation The transformer hanging cover is inspired by a 120mm long copper wire.

(4) The core insulation is damp or damaged, such as sludge and moisture deposited on the bottom, the insulation resistance decreases, the clamp insulation, pad insulation, iron box insulation (cardboard or wood block) is damp or damaged, etc., resulting in high resistance multi-point grounding of the core.

(5) The bearings of the submersible oil pump are worn, and metal powder enters the oil tank and accumulates at the bottom, forming a bridge under the action of electromagnetic attraction, connecting the lower rail to the pads or the bottom of the tank, causing multi-point grounding.

(6) Poor operation and maintenance, and no scheduled maintenance.

2. Testing and treatment methods for transformer core faults

1. Testing methods for transformer core faults

(1) Clamp ammeter method (online measurement). For transformers with external iron cores, the clamp ammeter method can be used to accurately test multi-point ground faults in the iron core without power outage. Measure the ground lead current regularly every year. Generally, the current should be below 100 mA. If it is greater than this value, monitoring should be strengthened. After the transformer is put into operation, measure the grounding wire resistance several times as the initial value. If the initial value itself is large, it means that the transformer itself has large magnetic leakage. If the measured values are not much different in the future, it can be considered as a fault-free grounding point. If the ground wire current is greater than 1 A and increases significantly compared with the initial value, it may be a low-resistance ground or metal ground fault, and this situation should be dealt with in time.

(2) Chromatographic analysis (charged oil extraction). Take a sample for chromatographic analysis. If the total hydrocarbons increase significantly, and methane and ethylene are the main components in the gas, while carbon monoxide and carbon dioxide gases have little change or remain basically unchanged compared to the past, it can be judged that the bare metal is overheated, and the core may be too much. Point grounding or damage to the edge between core silicon steel sheets requires further inspection. If acetylene appears in the above total hydrocarbons, it is likely that the unstable core is grounded at multiple points.

(3) Insulation resistance method (power outage test). Use a 2500-volt megger to measure the resistance between the core and the shell. If the insulation resistance is 200 megohms or above, it means the core is well insulated. If the megohmmeter indicates that the core and the shell are connected, you can use an ohmmeter to measure the resistance between the core and the shell. If the measured value is 200~400 ohms, it means that the core has a high-resistance grounding point, and it is necessary to conduct a multi-point ground fault on the core of the transformer. deal with.

If the measured value is above 1000 ohms, the current flowing through the ground wire is small, and it is difficult to eliminate the fault. You can continue to operate without processing, and conduct regular online monitoring, such as clamp-type ammeter method (those with iron core outer leads), oil chromatography analysis Method, deal with the exception after finding it. If the measured value is 1-2 ohms, it is judged that the core has a metal grounding point and the transformer must be processed.

2. How to deal with multi-point grounding in the transformer core

(1) If the core has an external ground wire, a resistor can be connected in series on the core ground loop to limit the core ground current. This method can only be used as an emergency measure.

(2) Core grounding faults caused by metal foreign matter can usually be found by inspecting the hanging hood.

(3) For ground faults caused by core burrs and metal powder accumulation, the capacitive discharge impact method, AC arc method, and high current impact method are more effective.

3. Quality standards for power transformer core maintenance

1. The core should be flat, the insulating paint film should not fall off, and the laminations should be tightly stacked. The silicon steel sheets on the sides should not be warped or wavy. The surface of each part of the core should be free of grease and impurities. There should be no short circuit or overlap between the sheets. The seam gap meets the requirements;

2. Good insulation should be maintained between the iron core and the upper and lower clamps, square irons, pressure plates and foot plates;

3. There should be an obvious and even gap between the steel pressure plate and the iron core; the insulation pressure plate should be kept intact, without damage or cracks, and have appropriate fastening;

4. The steel pressure plate must not form a closed loop and should be grounded at one point;

5. After opening the connecting piece between the upper clamp and the iron core and the connecting piece between the steel pressure plate and the upper clamp, measure the insulation resistance between the iron core and the upper and lower clamps and between the steel pressure plate and the iron core. There should be no significant change compared with previous tests. ;

6. Tighten the bolts, and the positive and negative pressure nails and locking nuts on the clamp are not loose, and are in good contact with the insulating washers. There are no traces of discharge burns, and there is a sufficient distance between the back pressure nail and the upper clamp;

7. After tightening the through-bolts, the insulation resistance has no significant change compared with previous tests;

8. The oil passage should be smooth, the oil passage pads should not fall off or be blocked, and should be arranged neatly;

9. The core is only allowed to be grounded at one point. The grounding piece should be a copper piece with a thickness of 0.5mm and a width of not less than 30mm. It should be inserted between the 3rd and 4th grade iron cores. For large transformers, the insertion depth should not be less than 80mm. The exposed part should be wrapped with insulation to prevent short circuit of the core. ;

10. It should be fastened and have sufficient mechanical strength. It should be well insulated and should not form a loop or come into contact with the core;

11. Good insulation and reliable grounding.

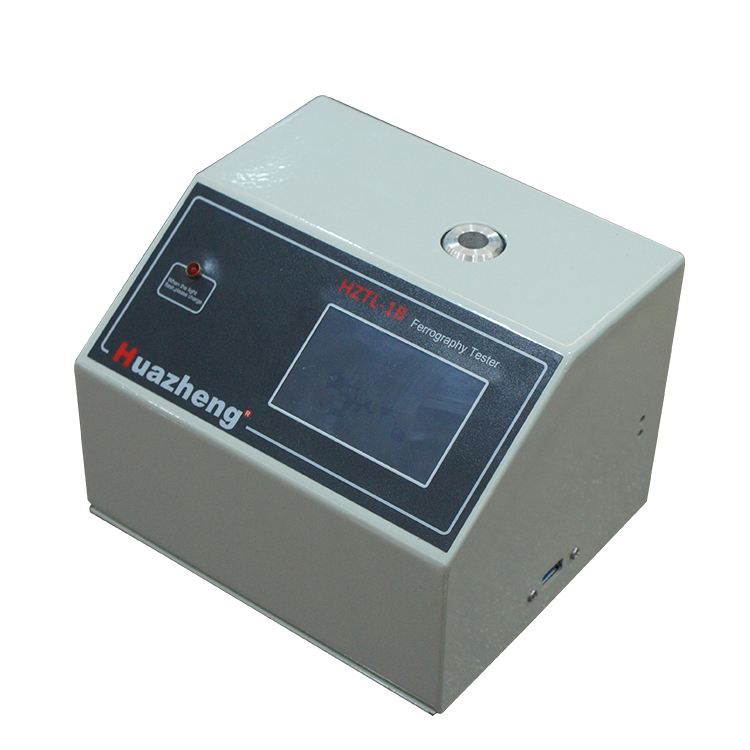

HZTL-1B Portable Oil Ferrography Tester