1. The standard material contains water

During the test, if the flash point standard material used contains water, the water dispersed in the oil will vaporize to form water vapor during the heating and determination of the flash point, and sometimes bubbles will be formed to cover the liquid surface. It affects the normal vaporization of oil products, delays the flash fire time, and makes the measurement results higher. Under normal circumstances, flash point reference materials are dehydrated and sealed for direct use. However, the specifications of flash point reference materials are generally (100~250) mL, and the amount required for one measurement is about (50~70) mL. , so it is often the case that the flash point standard material is not used up after being unpacked and used for measurement. If it is not stored properly at this time. If the ambient humidity is high, the sample may contain water. It is generally believed that when the moisture content of the sample is greater than 0.05%, it must be dehydrated before conducting the flash point test.

2. Setting of pre-flash value

It is necessary to set the pre-flash value before measuring the flash point. If the pre-flash value is set too low, the temperature at which ignition will begin will be advanced. Part of the oil and gas will be released and consumed during each ignition, causing the temperature to reach the lower explosion limit to rise and the measurement results to be biased. high. If the pre-flash value is set too high, a higher concentration of oil and gas will locally accumulate in the oil cup when ignition begins, causing early flash ignition and resulting in low measurement results.

3. Ignition control

When igniting, the size of the spherical flame, the distance from the sample liquid level, and the residence time should all be implemented in accordance with national standards. If the diameter of the spherical flame is too large, the distance from the liquid level is close, and the residence time is too long, the ignition will be advanced. , the measurement result is low. If you use electric ignition, you need to pay attention to the brightness of the ignition wire. At present, most closed flash point meters with electric ignition generally find that after a period of use, the brightness of the igniter decreases and the temperature does not meet the usage requirements. Therefore, when measuring the flash point meter, if it is a gas ignition method, you must always pay attention to the size of the flame, because in many cases the instability of the gas source will directly affect the flame size. : If it is an electric ignition method, you need to observe the brightness of the igniter. If the brightness is insufficient, you need to polish the metal coil on the igniter first, or it is recommended to replace the ignition coil with a full platinum one.

4. Requirements for the operation of closed flash point tester

According to the standard, the sample in the cup must be installed at the annular line. Too much or too little filling will change the height of the space above the liquid level, which will affect the mixing concentration of oil vapor and air, making the measurement results inaccurate. When pouring the sample, sometimes the part above the ring line will be stained. At this time, it should be wiped carefully and there should be no air bubbles on the liquid surface, otherwise it will greatly affect the flash point measurement results. When adding a sample, first place the test cup steadily on the instrument, and then carefully add the sample to the scale. In actual operation, some personnel are accustomed to pouring the sample first, and then placing the test cup with the sample on the instrument, so that The liquid surface may shake during the movement and stick to the cup wall or rim, causing inaccurate measurement results. This is more obvious for some samples with higher viscosity.

5. Atmospheric pressure

The flash point of oil is related to the external pressure, and the air pressure is low. Oils are volatile and have a lower flash point, whereas conversely, the flash point is higher. For example, GB/r261-2008 regulations. 101.3kPa is used as the base pressure for flash point measurement. If there is a deviation, pressure correction is required. The correction formula is given within the range of atmospheric pressure (98.0104.7)kPa. Therefore, for closed IZl flash point standards set according to this standard, it is necessary to ensure that the ambient atmospheric pressure is within the above range during testing. At the same time, for instruments without pressure correction, an additional certified air box pressure is required. The table, after correction, is compared with the standard value of the closed flash point reference material to calculate the measurement error.

6. Test temperature

The test temperature of the closed flash point tester is mainly the ambient temperature during the test and the temperature of the instrument itself (closed cup, heater). When measuring a lower flash point temperature, such as when testing diesel and kerosene, the test temperature directly affects the volatilization rate of oil vapor, which in turn affects the actual measured value of the flash point. The higher the test temperature, the lower the measured flash point value, and vice versa. The measured flash point value is higher.

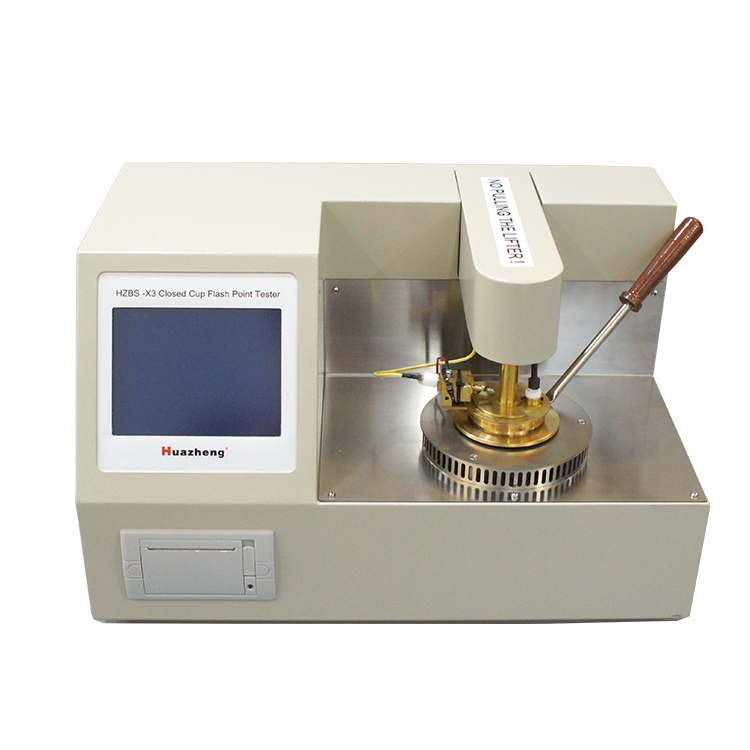

HZBS-X3 Closed Cup Flashpoint Measuring